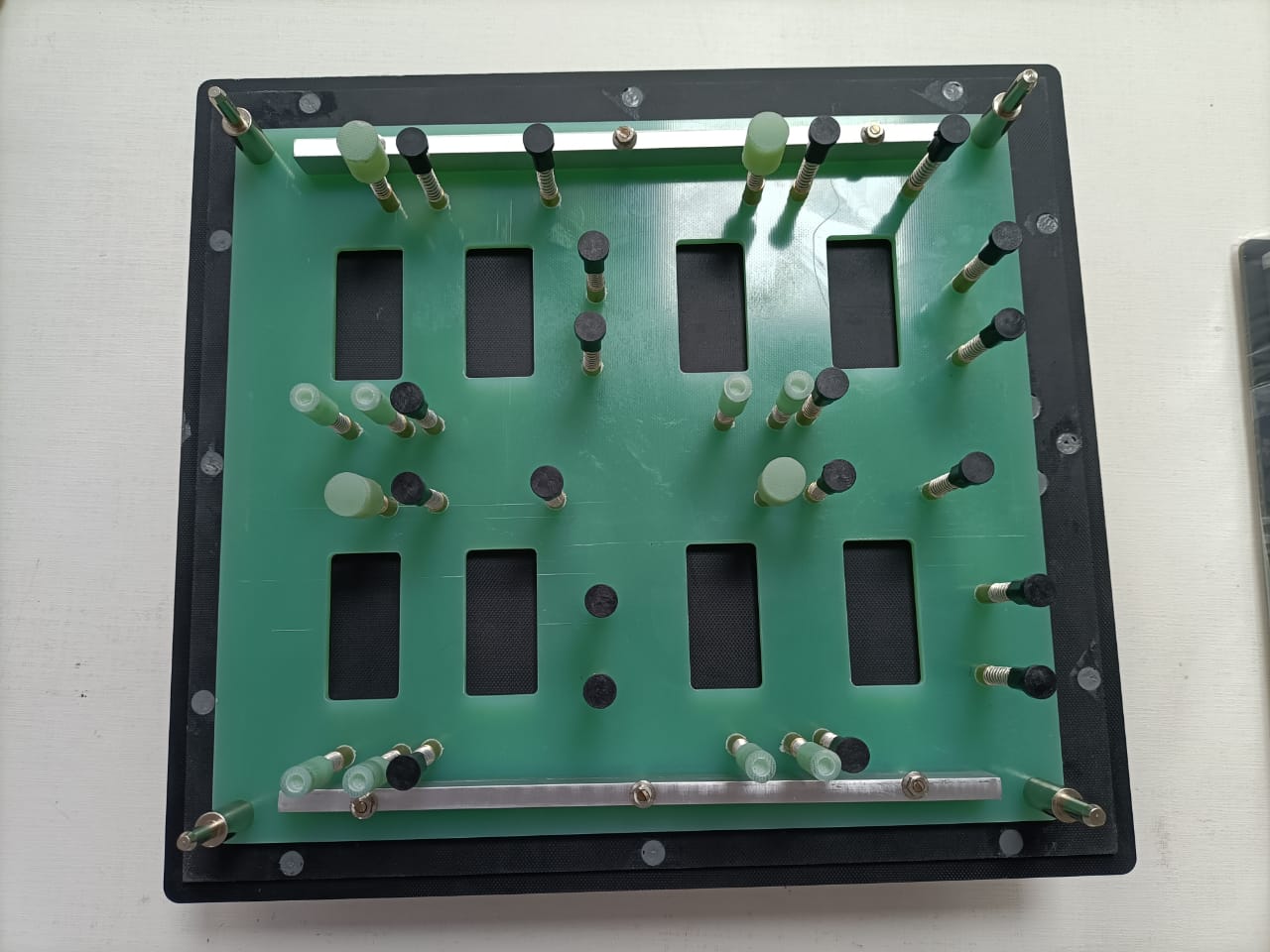

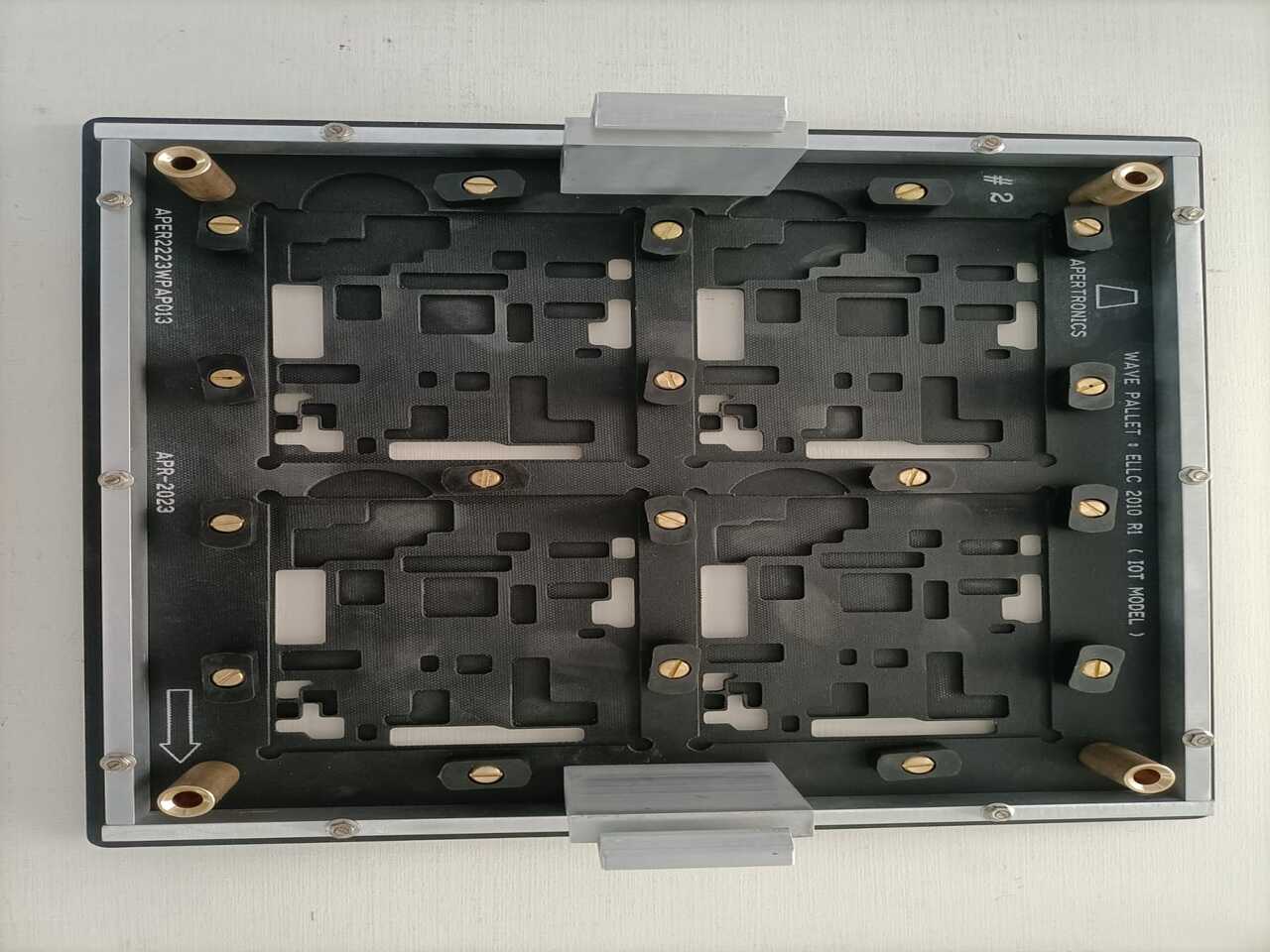

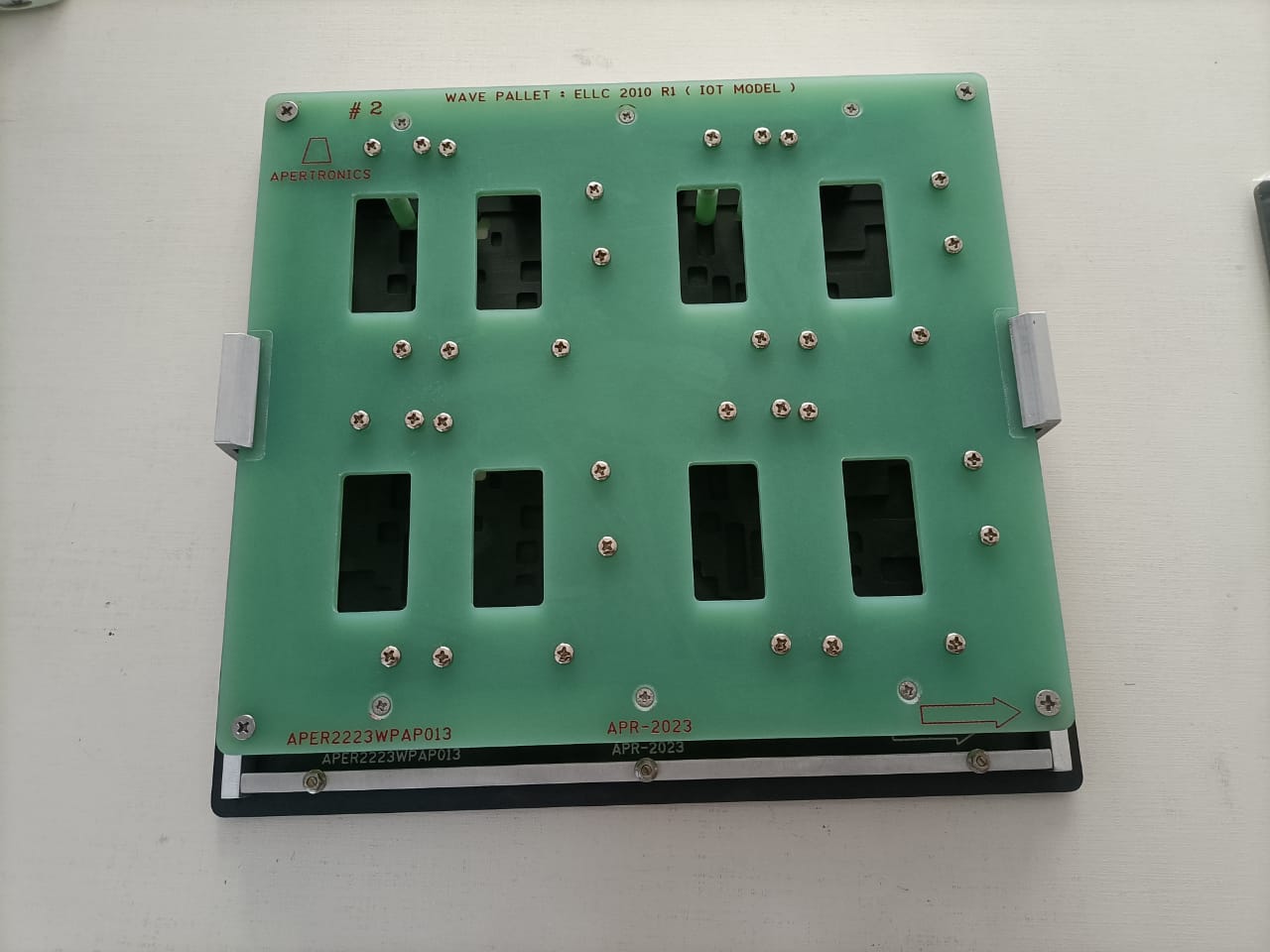

wave soldering still remains a popular process used in the manufacture of printed circuit boards to solder through-hole components. Wave solder pallets (also known as wave solder fixtures) are used during wave soldering on circuit boards thatsolder pallets (also known as wave solder fixtures) are used during wave soldering on circuit boards that require thermal or solder protection. Wave solder pallets are custom for a particular job. During the manufacturing process,material is removed from the pallet in areas where the printed circuit board needs to be exposed to solder. Material is left on the pallet in areas where the PCB needs to be covered in particular areas containing surface mount components, mounting holes, gold fingers and ground planes.

We only need some information for you to making the solder pallet,