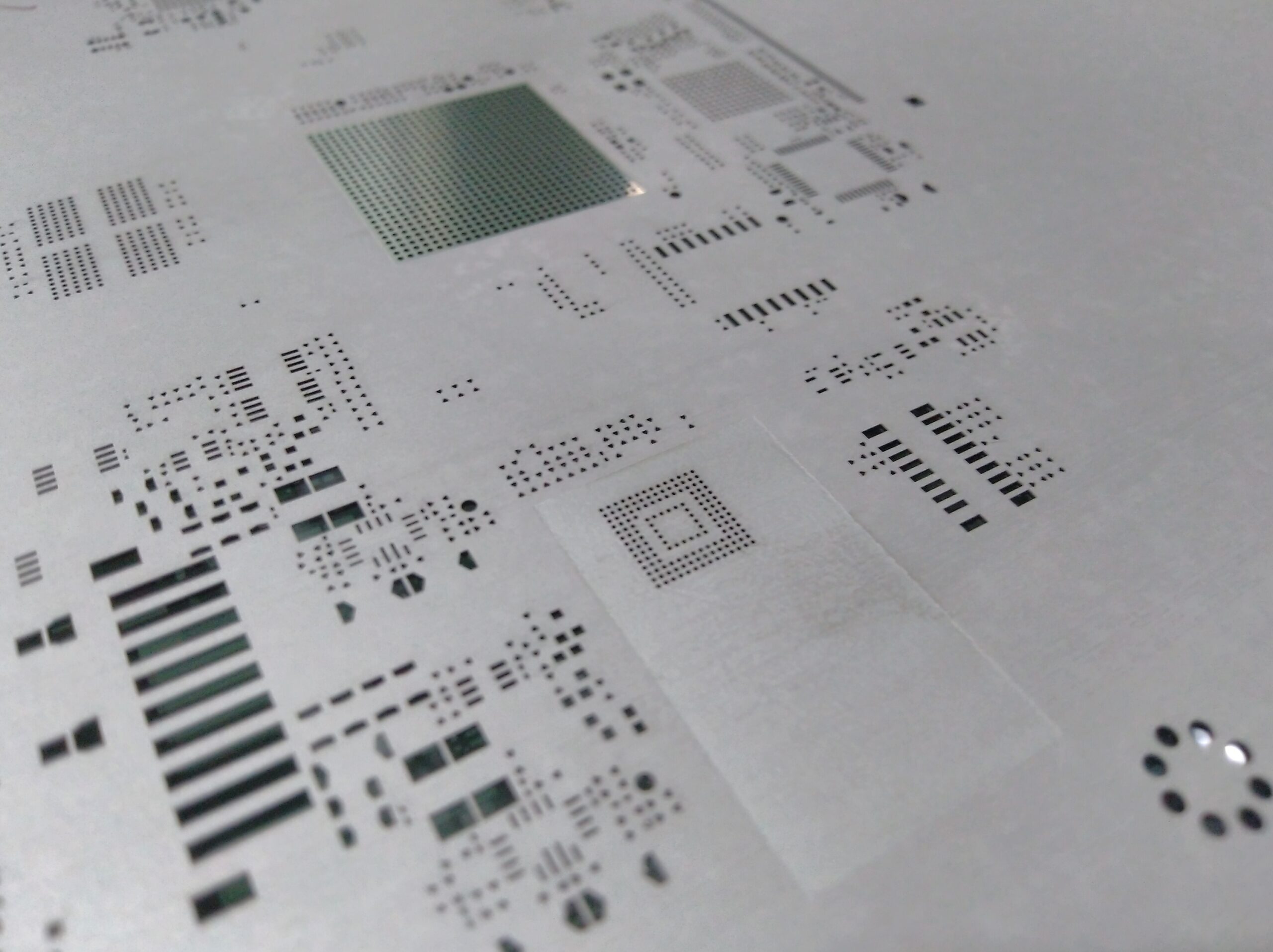

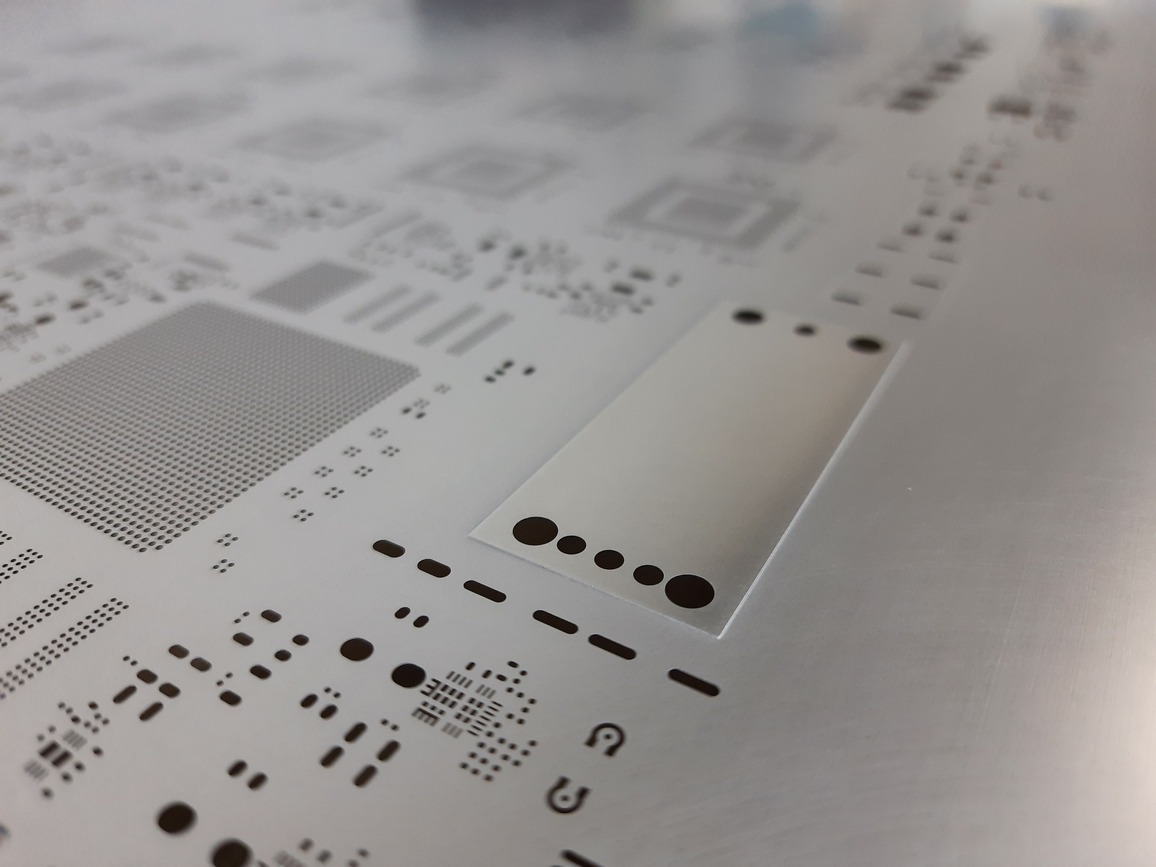

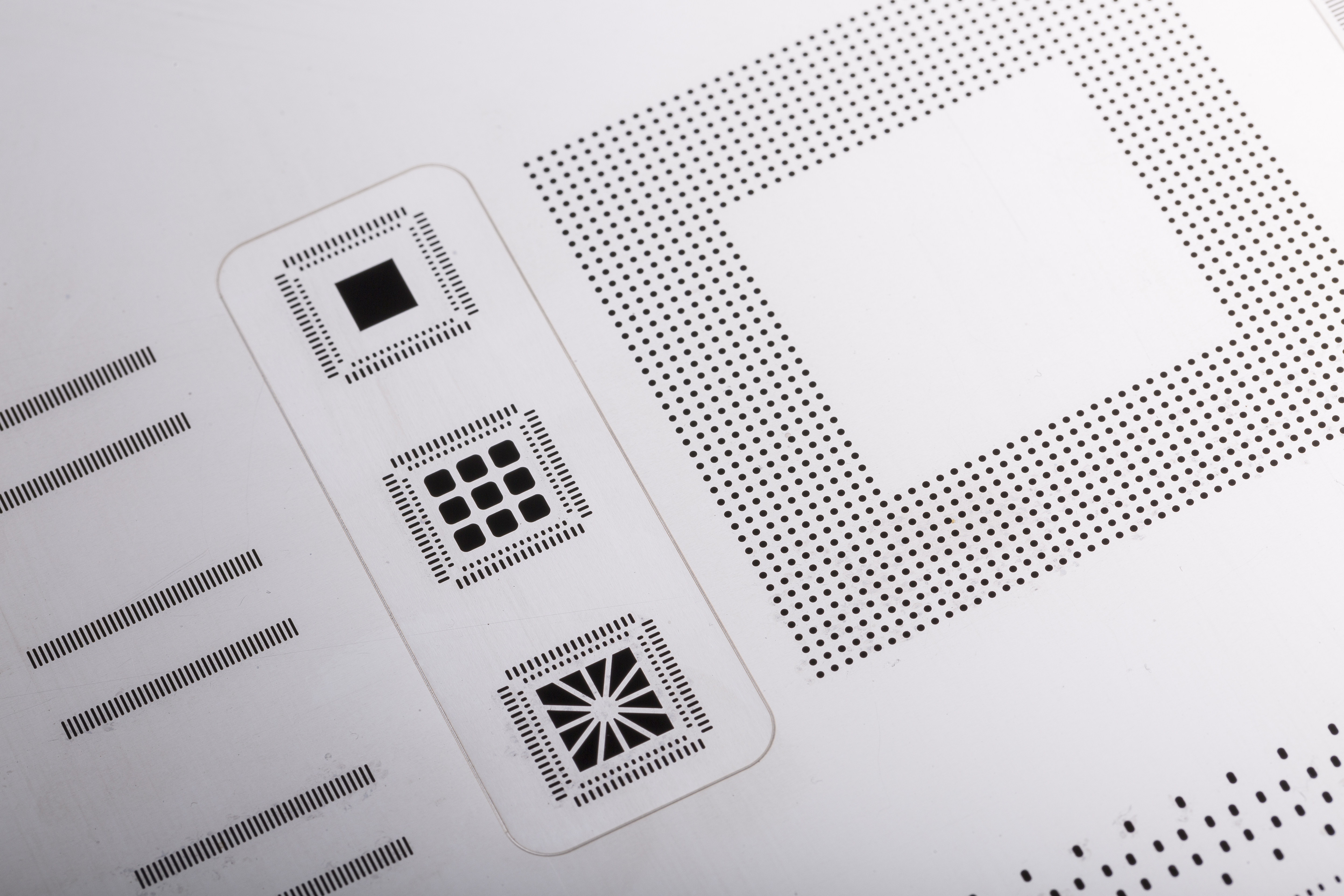

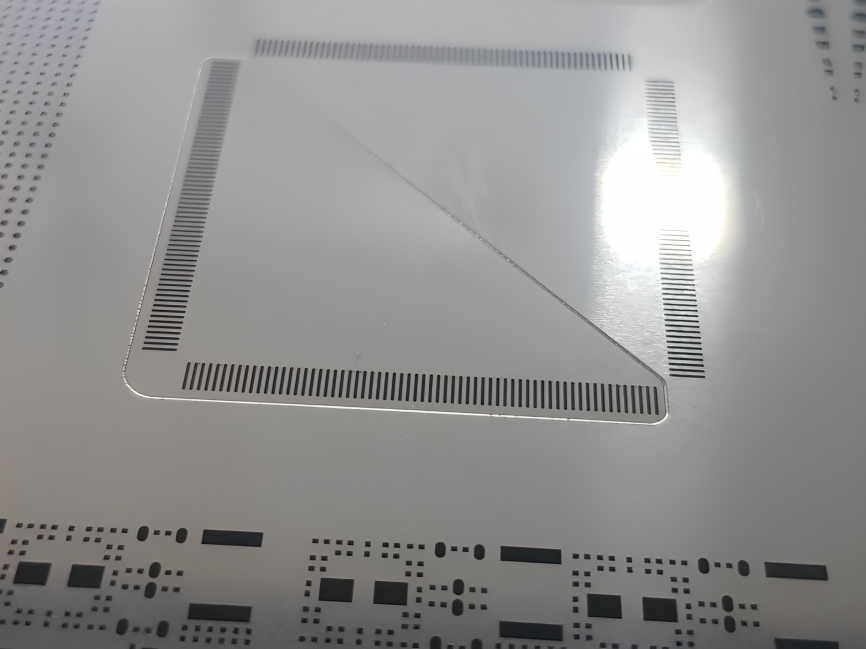

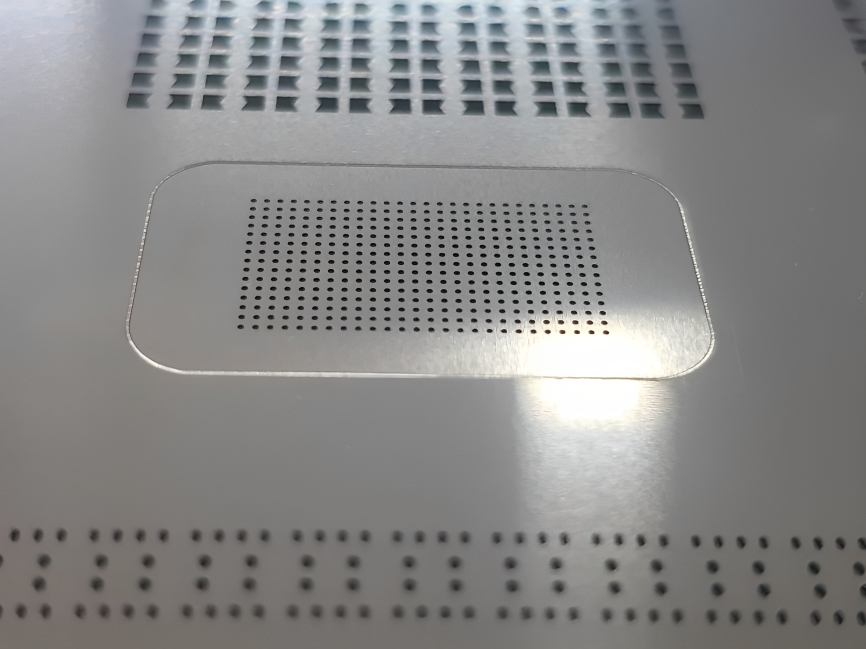

APERTRONICS as the technical ability to manufacture step stencils in both single and multi-process with new technology. Today's complex PCBs with their various and multi-process with new technology. Today's complex PCBs with their variousand multi-process with new technology. Today's complex PCBs with their various on the same stencil, this allows the ability to control solder paste deposition in fine pitch areas while printing sufficient solder on coarse pitch areas.

We are having chemical etching and new generation technology for step stencils.

Benefits: